Estimation of Damage Induced by Single-Hole Rock Blasting: A Review on Analytical, Numerical, and Experimental Solutions

Abstract

:1. Introduction

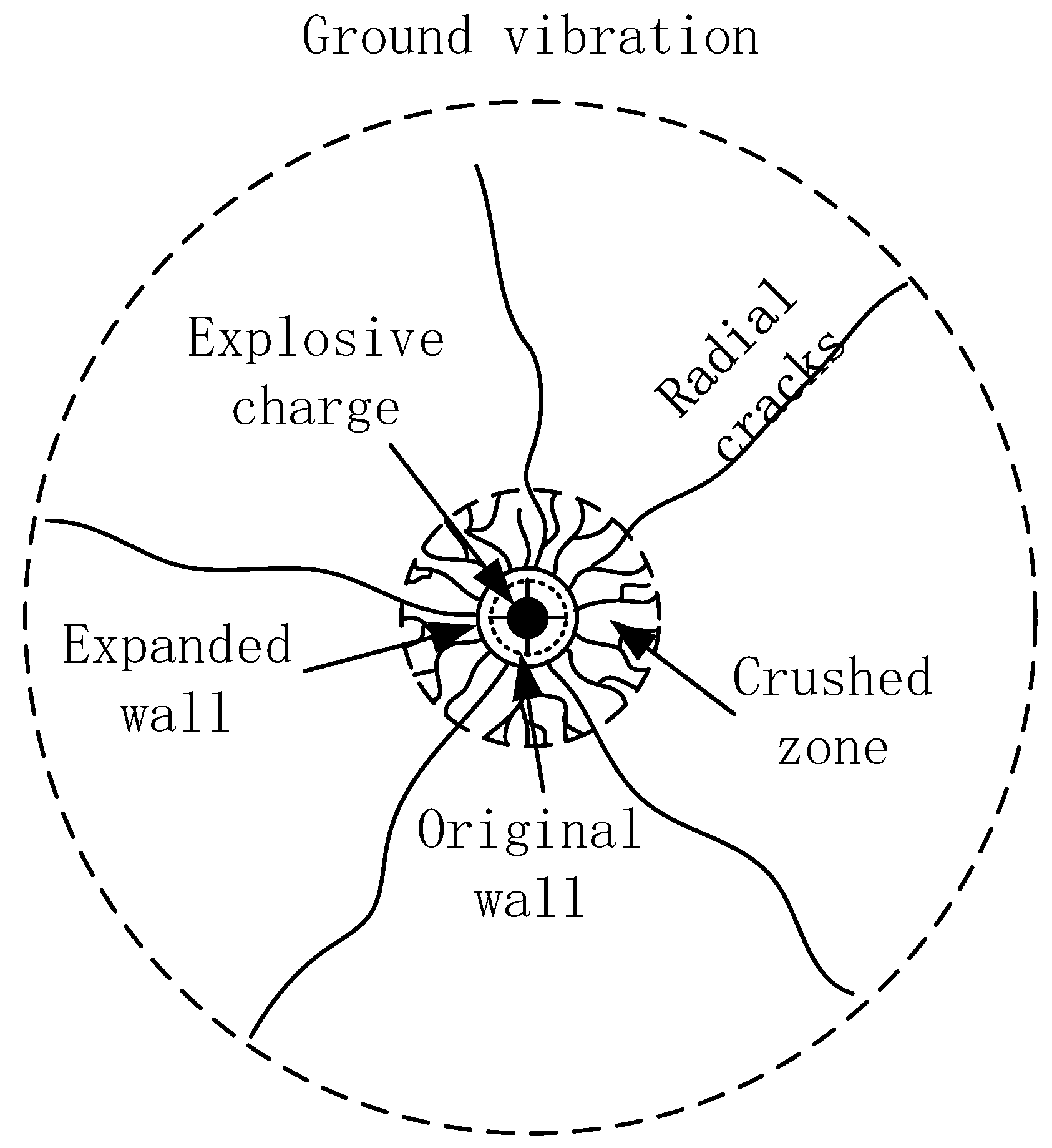

2. A Review on Explosion Mechanism

3. Damage Pattern

- The blast hole is expanded.

- A crushed zone is formed surrounding the blast hole.

- Radial cracks penetrate through the rock, causing a cracked zone.

- Explosion-induced waves affect the surrounding environment, producing some ground vibrations.

4. Estimation of Induced Damage

4.1. Analytical Approach

4.1.1. Damage Prediction Using PPV

- Only the magnitude of the PPV is considered and the direction of the PPV is neglected.

- Only the explosive weight is taken into account, and other characteristics are ignored.

- To determine the parameters K, , and , further laboratory or in-situ tests are required, which are difficult to conduct.

4.1.2. Damage Prediction Using Borehole Pressure

Mosinets’ Model

Drukovanyi’ Model

Senuk’s Model

Szuladzinski’s Model

SveBeFo Model

Quasi-Static Model

- Step 1

- Calculate from Equation (20)

- Step 2

- Approximate a value for (this value is approximated in this step and later modified in a cyclic process)

- Step 3

- Substitute and in Equation (21) and calculate

- Step 4

- Substitute in Equation (22) and determine

- Step 5

- Step 6

- Substitute in Equation (19) to assess if equality is achieved (if so, is the final answer. Otherwise, the steps 2–6 should be repeated until the final answer is reached).

Djordjevic’s Model

Kanchibotla Model

Johnson’s Model

Modified Ash’s Model

4.2. Numerical Approach

4.3. Experimental Approach

- Primary cracks due to the high amplitude of stress waves

- Further development of cracks due to gas penetration

5. Discussion

5.1. Comparison of Different Models

5.2. Probabilistic Approaches

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kanchibotla, S.; Morrell, S.; Valery, W.; Loughlin, P.O. Exploring the effect of blast design on SAG mill throughput at KCGM. In Proceedings of the Mine to Mill Conference, Brisbane, Australia, 11–14 October 1998. [Google Scholar]

- Esen, S.; Onederra, I.; Bilgin, H. Modelling the size of the crushed zone around a blasthole. Int. J. Rock Mech. Min. Sci. 2003, 40, 485–495. [Google Scholar] [CrossRef]

- Ouchterlony, F.; Moser, P. Lessons from single-hole blasting in mortar, concrete and rocks. In Rock Fragmentation by Blasting; Singh, P.K., Sinha, A., Eds.; CRC Press: London, UK, 2012; pp. 3–14. [Google Scholar]

- Zhang, Z.X. Rock Fracture and Blasting, Theory and Applications; Butterworth-Heinemann: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Chi, L.Y.; Zhang, Z.X.; Aalberg, A.; Yang, J.; Li, C.C. Fracture processes in granite blocks under blast loading. Rock Mech. Rock Eng. 2019, 52, 853–868. [Google Scholar] [CrossRef]

- Sun, C. Damage Zone Prediction for Rock Blasting. Ph.D. Thesis, University of Utah, Salt Lake City, UT, USA, 2013. [Google Scholar]

- Zou, D. Theory and Technology of Rock Excavation for Civil Engineering, 1st ed.; Springer: Singapore, 2017. [Google Scholar]

- Singh, S. Blast damage control in jointed rock mass. Fragblast Int. J. Blasting Fragm. 2005, 9, 175–187. [Google Scholar] [CrossRef]

- Chen, M.; Lu, W.B.; Yan, P.; Hu, Y.G. Blasting excavation induced damage of surrounding rock masses in deep-buried tunnels. KSCE J. Civ. Eng. 2015, 20, 933–942. [Google Scholar] [CrossRef]

- Kanchibotla, S. Optimum Blasting? Is it Minimum Cost Per Broken Rock or Maximum Value Per Broken Rock? Fragblast Int. J. Blasting Fragm. 2003, 7, 35–48. [Google Scholar] [CrossRef]

- Performance of Explosives and New Developments, 1st ed.; Mohanty, B.; Singh, V.K. (Eds.) CRC Press: New Delhi, India, 2012. [Google Scholar]

- Leng, Z.; Lu, W.; Chen, M.; Yan, P.; Hu, Y. A new theory of rock-explosive matching based on the reasonable control of crushed zone. Engineering 2014, 12, 32–38. [Google Scholar]

- Trivino, L.; Mohanty, B. Assessment of crack initiation and propagation in rock from explosion-induced stress waves and gas expansion by cross-hole seismometry and FEM-DEM method. Int. J. Rock Mech. Min. Sci. 2015, 77, 287–299. [Google Scholar] [CrossRef]

- Bhandari, S. Engineer Rock Blasting Operations, 1st ed.; CRC Press: Boca Raton, FL, USA, 1997. [Google Scholar]

- Fairhurst, C. Comprehensive Rock Comprehensive Rock Engineering: Principles, Practice and Projects, Analysis and Design Methods, 2nd ed.; Pergamon Pr: Oxford, UK, 1995. [Google Scholar]

- Qiu, X.; Shi, X.; Zhang, S.; Liu, B.; Zhou, J. Experimental Study on the Blasting Performance of Water-Soil Composite Stemming in Underground Mines. Adv. Mater. Sci. Eng. 2018, 2018. [Google Scholar] [CrossRef] [Green Version]

- Xia, Y.; Jiang, N.; Zhou, C.; Luo, X. Safety assessment of upper water pipeline under the blasting vibration induced by Subway tunnel excavation. Eng. Fail. Anal. 2019, 104, 626–642. [Google Scholar] [CrossRef]

- Ouchterlony, F.; Nyberg, U.; Olsson, M.; Bergqvist, I.; Granlund, L.; Grind, H. Where does the explosive energy in rock blasting rounds go? Sci. Technol. Energetic Mater. 2004, 65, 54–63. [Google Scholar]

- Souissi, S.; Hamdi, E.; Sellami, H. Microstructure effect on hard rock damage and fracture during indentation process. Geotech. Geol. Eng. 2015, 33, 1539–1550. [Google Scholar] [CrossRef]

- Fourney, W.L. The role of stress waves and fracture mechanics in fragmentation. In Proceedings of the 11th International Symposium on Rock Fragmentation by Blasting, Sydney, Australia, 24–26 August 2015; The Australasian Institute of Mining and Metallurgy: Carlton, Australia, 2015; pp. 27–40. [Google Scholar]

- Persson, P.; Ladegaard-Pedersen, A.; Kihlstrom, B. The influence of borehole diameter on the rock blasting capacity of an extended explosive charge. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1969, 6, 277–284. [Google Scholar] [CrossRef]

- Brinkmann, J. An experimental study of the effects of shock and gas penetration in blasting. In Proceedings of the 3rd International Symposium on Rock Fragmentation by Blasting, Brisbane Australia, 26–31 August 1990; pp. 55–66. [Google Scholar]

- Wang, C.; Zhu, Z.M.; Zheng, T. The fracturing behavior of detected rock under blasting loads. In Applied Mechanics and Materials; Trans Tech Publications: Stafa-Zurich, Switzerland, 2012; Volume 142, pp. 193–196. [Google Scholar] [CrossRef]

- Saharan, M.; Mitri, H.; Jethwa, J. Rock fracturing by explosive energy: Review of state-of-the-art. Fragblast Int. J. Blasting Fragm. 2006, 10, 61–81. [Google Scholar] [CrossRef]

- Banadaki, M.D.; Mohanty, B. Numerical simulation of stress wave induced fractures in rock. Int. J. Impact Eng. 2012, 40–41, 16–25. [Google Scholar] [CrossRef]

- Adhikari, G.; Theresraj, A.; Venkatesh, H.; Balachander, R.; Gupta, R. Ground vibration due to blasting in limestone quarries. Fragblast Int. J. Blasting Fragm. 2010, 8, 85–94. [Google Scholar] [CrossRef]

- Chi, L.Y.; Zhang, Z.X.; Aalberg, A.; Yang, J.; Li, C.C. Measurement of shock pressure and shock-wave attenuation near a blast hole in rock. Int. J. Impact Eng. 2019, 125, 27–38. [Google Scholar] [CrossRef]

- Olsson, M.; Ouchterlony, F. New Formula for Blast Induced Damage in the Remaining Rock (Title in Swedish: Ny skadezonsformel for skonsam sprangning); Technical Report SveBeFo Rapport 65; Swedish Rock Engineering Research: Stockholm, Sweden, 2003. [Google Scholar]

- Asl, P.F.; Monjezi, M.; Hamidi, J.K.; Armaghani, D.J. Optimization of flyrock and rock fragmentation in the Tajareh limestone mine using metaheuristics method of firefly algorithm. Eng. Comput. 2018, 34, 241–251. [Google Scholar] [CrossRef]

- Leng, Z.; Fan, Y.; Gao, Q.; Hu, Y. Evaluation and optimization of blasting approaches to reducing oversize boulders and toes in open-pit mine. Int. J. Min. Sci. Technol. 2020, 30, 373–380. [Google Scholar] [CrossRef]

- Ma, L.; Lai, X.; Zhang, J.; Xiao, S.; Zhang, L.; Tu, Y. Blast-Casting Mechanism and Parameter Optimization of a Benched Deep-Hole in an Opencast Coal Mine. Shock Vib. 2020, 2020. [Google Scholar] [CrossRef]

- Verma, H.; Samadhiya, N.; Singh, M.; Goel, R.; Singh, P. Blast induced rock mass damage around tunnels. Tunn. Undergr. Space Technol. 2018, 71, 149–158. [Google Scholar] [CrossRef]

- Jang, H.; Kawamura, Y.; Shinji, U. An empirical approach of overbreak resistance factor for tunnel blasting. Tunn. Undergr. Space Technol. 2019, 92. [Google Scholar] [CrossRef]

- Silva, J.; Worsey, T.; Lusk, B. Practical assessment of rock damage due to blasting. Int. J. Min. Sci. Technol. 2019, 29, 379–385. [Google Scholar] [CrossRef]

- Srirajaraghavaraju, R.R. Transmitted Pressure and Resulting Crack Network in Selected Rocks from Single-Hole Blasts in Laboratory-Scale Experiments. Master’s Thesis, University of Toronto, Toronto, ON, Canada, 2014. [Google Scholar]

- Johnson, C.E. Fragmentation Analysis in the Dynamic Stress Wave Collision Regions in Bench Blasting. Ph.D. Thesis, University of Kentucky, Lexington, KY, USA, 2014. [Google Scholar]

- Guo, Y.; Han, Z.; Guo, H.; Wang, T.; Liu, B.; Wang, D. Numerical simulation damage analysis of pipe-cement-rock combination due to the underwater explosion. Eng. Fail. Anal. 2019, 105, 584–596. [Google Scholar] [CrossRef]

- Wei, X.; Zhao, Z.; Gu, J. Numerical simulations of rock mass damage induced by underground explosion. Int. J. Rock Mech. Min. Sci. 2009, 46, 1206–1213. [Google Scholar] [CrossRef]

- Yang, R.; Wang, Y.; Ding, C. Laboratory study of wave propagation due to explosion in a jointed medium. Int. J. Rock Mech. Min. Sci. 2016, 81, 70–78. [Google Scholar] [CrossRef]

- Persson, P.A.; Holmberg, R.; Lee, J. Rock Blasting and Explosives Engineering, 1st ed.; CRC Press: Boca Raton, FL, USA, 1993. [Google Scholar]

- Jommi, C.; Pandolf, A. Vibrations induced by blasting in rock: A numerical approach. Riv. Ital. Geotec. 2008, 2, 77–94. [Google Scholar]

- Fleetwood, K.G.; Villaescusa, E.; Li, J. Limitations of using ppv damage models to predict rock mass damage. In Proceedings of the Thirty-Fifth Annual Conference on Explosives and Blasting Technique, Denver, CO, USA, 8–11 February 2009; International Society of Explosives Engineers: Denver, CO, USA, 2009; Volume 1, pp. 1–15. [Google Scholar]

- Duan, K.; Kwok, C.Y. Evolution of stress-induced borehole breakout in inherently anisotropic rock: Insights from discrete element modeling. J. Geophys. Res. Solid Earth 2016, 121, 2361–2381. [Google Scholar] [CrossRef] [Green Version]

- Parra, L.F.T. Study of Blast-Induced Damage in Rock with Potential Application to Open Pit and Underground Mines. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2012. [Google Scholar]

- Ma, G.; Hao, H.; Wang, F. Simulations of explosion-induced damage to underground rock chambers. J. Rock Mech. Geotech. Eng. 2011, 3, 19–29. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Konietzky, H. Modelling of blast-induced fractures in jointed rock masses. Eng. Fract. Mech. 2009, 76, 1945–1955. [Google Scholar] [CrossRef]

- Mitelman, A.; Elmo, D. Modelling of blast-induced damage in tunnels using a hybrid finite-discrete numerical approach. J. Rock Mech. Geotech. Eng. 2014, 6, 565–573. [Google Scholar] [CrossRef] [Green Version]

- Bendezu, M.; Romanel, C.; Roehl, D. Finite element analysis of blast-induced fracture propagation in hard rocks. Comput. Struct. 2017, 182, 1–13. [Google Scholar] [CrossRef]

- Onederra, I.A.; Furtney, J.K.; Sellers, E.; Iverson, S. Modelling blast induced damage from a fully coupled explosive charge. Int. J. Rock Mech. Min. Sci. 2013, 58, 73–84. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hu, Y.g.; Liu, M.s.; Wu, X.x.; Zhao, G.; Li, P. Damage-vibration couple control of rock mass blasting for high rock slopes. Int. J. Rock Mech. Min. Sci. 2018, 103, 137–144. [Google Scholar] [CrossRef]

- Sun, X.J.; Sun, J.S. Research on the damage fracture of rock blasting based on velocity response spectrum. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2012; Volume 105, pp. 1521–1527. [Google Scholar] [CrossRef]

- Bauer, A.; Calder, P. Open Pit and Blast Seminar; Course No. 63321; Mining Engineering Department, Queens University: Kingston, ON, Canada, 1978. [Google Scholar]

- Mojtabai, N.; Beatty, S. An empirical approach to assessment of and prediction of damage in bench blasting. Trans. Inst. Min. Metall. 1995, 105, A75–A80. [Google Scholar]

- Holmberg, R.; Persson, P. The Swedish approach to contour blasting. In Proceedings of the Annual Conference on Explosives and Blasting Technique, New Orleans, LA, USA, 1–3 February 1978; International Society of Explosives Engineers: New Orleans, LA, USA, 1978; pp. 113–127. [Google Scholar]

- Aleksandrova, N.I.; Sher, Y.N. Effect of stemming on rock breaking with explosion of a cylindrical charge. J. Min. Sci. 1999, 35, 483–493. [Google Scholar] [CrossRef]

- Wang, M.; Yue, S.; Zhang, N.; Gao, K.; Wang, D. A method of calculating critical depth of burial of explosive charges to generate bulging and cratering in rock. Shock Vib. 2016, 1–11. [Google Scholar] [CrossRef]

- Hustrulid, W.; Lu, W. Some general design concepts regarding the control of blast-induced damage during rock slope excavation. In Proceedings of the 7th International Symposium on Rock Fragmentation by Blasting, Beijing, China, 11–15 August 2002; pp. 595–604. [Google Scholar]

- Mosinets, V.; Gorbacheva, N. A seismological method of determining the parameters of the zones of deformation of rock by blasting. Sov. Min. 1972, 8, 640–647. [Google Scholar] [CrossRef]

- Ilyushin, A. The Mechanics of a Continuous Medium; Izd-vo MGU: Moscow, Russia, 1971. (In Russian) [Google Scholar]

- Drukovanyi, M.F.; Kravtsov, V.; Chernyavskii, Y.; Shelenok, V.; Reva, N.; Zverkov, S. Calculation of fracture zones created by exploding cylindrical charges in ledge rocks. Sov. Min. 1976, 12, 292–295. [Google Scholar] [CrossRef]

- Senuk, V. The impulse from an explosion, and conditions for its greater utilization in crushing hard rock masses in blasting. Sov. Min. 1979, 15, 22–27. [Google Scholar] [CrossRef]

- Szuladzinski, G. Response of rock medium to explosive borehole pressure. In Rock Fragmentation by Blasting, Proceedings of The Fourth International Symposium on Rock Fragmentation by Blasting, FRAGBLAST-4, Vienna, Austria, 5–8 July 1993; Balkema: Rotterdam, The Netherland, 1993; pp. 17–23. [Google Scholar]

- Ash, R. The mechanics of rock breakage (part 1). Pit Quarry 1963, 56, 98–100. [Google Scholar]

- Ash, R. The mechanics of rock breakage (part 2)-standards blasting design. Pit Quarry 1963, 56, 119–122. [Google Scholar]

- Ash, R. The mechanics of rock breakage (part 3)-characteristics of explosives. Pit Quarry 1963, 56, 126–131. [Google Scholar]

- Ash, R. The mechanics of rock breakage (part 4)-material properties, powder factor, blasting cost. Pit Quarry 1963, 56, 109–118. [Google Scholar]

- Ouchterlony, F. Prediction of crack lengths in rock after cautious blasting with zero inter-hole delay. Int. J. Blasting Fragm. Fragblast 1997, 1, 417–444. [Google Scholar] [CrossRef] [Green Version]

- Ouchterlony, F.; Olsson, M.; Bergqvist, I. Towards new Swedish recommendations for cautious perimeter blasting. Int. J. Blasting Fragm. Fragblast 2002, 6, 235–261. [Google Scholar] [CrossRef] [Green Version]

- Sher, E.; Aleksandrova, N. Dynamics of development of crushing zone in elastoplastic medium in camouflet explosion of string charge. J. Min. Sci. 1997, 33, 529–535. [Google Scholar] [CrossRef]

- Sher, E.; Aleksandrova, N. Effect of borehole charge structure on the parameters of a failure zone in rocks under blasting. J. Min. Sci. 2007, 43, 409–417. [Google Scholar] [CrossRef]

- Hustrulid, W. Some comments regarding development drifting practices with special emphasis on caving applications. In Second International Symposium on Block and Sublevel Caving; Potvin, Y., Ed.; Australian Centre for Geomechanics: Perth, Australia, 2010; pp. 3–43. [Google Scholar]

- Djordjevic, N. A two-component model of blast fragmentation. In Proceedings of the 6th International Symposium for Rock Fragmentation by Blasting-Fragblast, Johannesburg, South Africa, 8–12 August 1999; pp. 213–219. [Google Scholar]

- Kanchibotla, S.; Valery, W.; Morrell, S. Modelling fines in blast fragmentation and its impact on crushing and grinding; Australasian Institute of Mining and Metallurgy Publication Series. In Proceedings of the Explo 99: A Conference on Rock Breaking, Kalgoorlie, WA, USA, 7–11 November 1999. [Google Scholar]

- Johnson, J. The Hustrulid Bar—A Dynamic Strength Test and Its Application to the Cautious Blasting of Rock. Ph.D. Thesis, The Unversity of Utah, Salt Lake, UT, USA, 2010. [Google Scholar]

- Saharan, M.R.; Mitri, H.S. Numerical Procedure for Dynamic Simulation of Discrete Fractures Due to Blasting. Rock Mech. Rock Eng. 2008, 41, 641–670. [Google Scholar] [CrossRef]

- Zhu, W.; Wei, J.; Zhao, J.; Niu, L. 2D numerical simulation on excavation damaged zone induced by dynamic stress redistribution. Tunn. Undergr. Space Technol. 2014, 43, 315–326. [Google Scholar] [CrossRef]

- Goodarzi, M.; Mohammadi, S.; Jafari, A. Numerical analysis of rock fracturing by gas pressure using the extended finite element method. Pet. Sci. 2015, 12, 304–315. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.; Lu, W.; Chen, M.; Yan, P.; Zhang, Y. Numerical simulation of the complete rock blasting response by SPH–DAM–FEM approach. Simul. Model. Pract. Theory 2015, 56, 55–68. [Google Scholar] [CrossRef]

- Yang, J.; Yao, C.; Jiang, Q.; Lu, W.; Jiang, S. 2D numerical analysis of rock damage induced by dynamic in-situ stress redistribution and blast loading in underground blasting excavation. Tunn. Undergr. Space Technol. 2017, 70, 221–232. [Google Scholar] [CrossRef]

- Hu, Y.; Lu, W.; Wu, X.; Liu, M.; Li, P. Numerical and experimental investigation of blasting damage control of a high rock slope in a deep valley. Eng. Geol. 2018, 237, 12–20. [Google Scholar] [CrossRef]

- Jayasinghe, L.; Shang, J.; Zhao, Z.; Goh, A. Numerical investigation into the blasting-induced damage characteristics of rocks considering the role of in-situ stresses and discontinuity persistence. Comput. Geotech. 2019, 116, 1–13. [Google Scholar] [CrossRef]

- Yilmaz, O.; Unlu, T. Three dimensional numerical rock damage analysis under blasting load. Tunn. Undergr. Space Technol. 2013, 38, 266–278. [Google Scholar] [CrossRef]

- Hu, R.; Zhu, Z.; Xie, J.; Xiao, D. Numerical study on crack propagation by using softening model under blasting. Adv. Mater. Sci. Eng. 2015, 2015, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Yang, T.; Zhang, P.; Zhou, J.; Yu, Q.; Deng, W. The analysis of rock damage process based on the microseismic monitoring and numerical simulations. Tunn. Undergr. Space Technol. 2017, 69, 1–17. [Google Scholar] [CrossRef]

- Jessu, K.; Spearing, A.; Sharifzadeh, M. A Parametric Study of Blast Damage on Hard Rock Pillar Strength. Energies 2018, 11, 1901. [Google Scholar] [CrossRef] [Green Version]

- Lak, M.; Fatehi Marji, M.; Yarahmadi Bafghi, A.; Abdollahipour, A. Analytical and numerical modeling of rock blasting operations using a two-dimensional elasto-dynamic Green’s function. Int. J. Rock Mech. Min. Sci. 2019, 114, 208–217. [Google Scholar] [CrossRef]

- Zhou, M.; Shadabfar, M.; Huang, H.; Leung, Y.F.; Uchida, S. Meta-modelling of coupled thermo-hydro-mechanical behaviour of hydrate reservoir. Comput. Geotech. 2020, 128, 103848. [Google Scholar] [CrossRef]

- Aliabadian, Z.; Sharafisafa, M.; Mortazavi, A.; Maarefvand, P. Wave and fracture propagation in continuum and faulted rock masses: Distinct element modeling. Arab. J. Geosci. 2014, 7, 5021–5035. [Google Scholar] [CrossRef]

- Deng, X.; Zhu, J.; Chen, S.; Zhao, Z.; Zhou, Y.; Zhao, J. Numerical study on tunnel damage subject to blast-induced shock wave in jointed rock masses. Tunn. Undergr. Space Technol. 2014, 43, 88–100. [Google Scholar] [CrossRef]

- Sharafisafa, M.; Aliabadian, Z.; Alizadeh, R.; Mortazavi, A. Distinct element modelling of fracture plan control in continuum and jointed rock mass in presplitting method of surface mining. Int. J. Min. Sci. Technol. 2014, 24, 871–881. [Google Scholar] [CrossRef]

- Bai, Q.S.; Tu, S.H.; Zhang, C. DEM investigation of the fracture mechanism of rock disc containing hole(s) and its influence on tensile strength. Theor. Appl. Fract. Mech. 2016, 86, 197–216. [Google Scholar] [CrossRef]

- Yin, T.; Zhang, S.; Li, X.; Bai, L. A numerical estimate method of dynamic fracture initiation toughness of rock under high temperature. Eng. Fract. Mech. 2018, 204, 87–102. [Google Scholar] [CrossRef]

- Yuan, W.; Su, X.; Wang, W.; Wen, L.; Chang, J. Numerical study of the contributions of shock wave and detonation gas to crack generation in deep rock without free surfaces. J. Pet. Sci. Eng. 2019, 177, 699–710. [Google Scholar] [CrossRef]

- Potyondy, D.O.; Cundall, P.A. A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 1329–1364. [Google Scholar] [CrossRef]

- Fakhimi, A.; Lanari, M. DEM-SPH simulation of rock blasting. Comput. Geotech. 2014, 55, 158–164. [Google Scholar] [CrossRef]

- An, H.; Liu, H.; Han, H.; Zheng, X.; Wang, X. Hybrid finite-discrete element modelling of dynamic fracture and resultant fragment casting and muck-piling by rock blast. Comput. Geotech. 2017, 81, 322–345. [Google Scholar] [CrossRef]

- Zhu, J.B.; Li, Y.S.; Wu, S.Y.; Zhang, R.; Ren, L. Decoupled explosion in an underground opening and dynamic responses of surrounding rock masses and structures and induced ground motions: A FEM-DEM numerical study. Tunn. Undergr. Space Technol. 2018, 82, 442–454. [Google Scholar] [CrossRef]

- Wang, Z.l.; Li, Y.c.; Wang, J. Numerical analysis of blast-induced wave propagation and spalling damage in a rock plate. Int. J. Rock Mech. Min. Sci. 2008, 45, 600–608. [Google Scholar] [CrossRef]

- Wang, Z.; Konietzky, H.; Shen, R. Coupled finite element and discrete element method for underground blast in faulted rock masses. Soil Dyn. Earthq. Eng. 2009, 29, 939–945. [Google Scholar] [CrossRef]

- Liu, C.; Yang, M.; Han, H.; Yue, W. Numerical simulation of fracture characteristics of jointed rock masses under blasting load. Eng. Comput. 2019, 36, 835–1851. [Google Scholar] [CrossRef]

- Lak, M.; Marji, M.F.; Bafghi, A.Y.; Abdollahipour, A. A coupled finite difference-boundary element method for modeling the propagation of explosion-induced radial cracks around a wellbore. J. Nat. Gas Sci. Eng. 2019, 64, 41–51. [Google Scholar] [CrossRef]

- Chi, L.Y.; Zhang, Z.X.; Aalberg, A.; Li, C.C. Experimental investigation of blast-induced fractures in rock cylinders. Rock Mech. Rock Eng. 2019, 52, 2569–2584. [Google Scholar] [CrossRef]

- Ge, J.; Li, G.Q.; Chen, S.W. Theoretical and experimental investigation on fragment behavior of architectural glass panel under blast loading. Eng. Fail. Anal. 2012, 26, 293–303. [Google Scholar] [CrossRef]

- Lownds, M. Measurement shock pressures in splitting of dimensional stone. In Proceedings of the 1st World Conference on Explosives and Blasting Technique, Munich, Germany, 6–8 September 2000; pp. 241–246. [Google Scholar]

- Talhi, K.; Hadjaj-Aoul, E.; Hannachi, E.B. Design of a model blasting system to measure peak P-wave stress. Acta Geod. Geophys. Hung. 2004, 39, 427–438. [Google Scholar] [CrossRef]

- Teowee, G.; Papillon, B. Measurement of borehole pressure during blasting. In Proceedings of the Rock Fragmentation by Blasting: Fragblast 10, New Delhi, India, 26–29 November 2012; pp. 599–605. [Google Scholar]

- Teowee, G.; Papillon, B. Monitoring of dynamic borehole pressures. In Proceedings of the 39th Annual Conference on Explosives and Blasting Techniques, Fort Worth, TX, USA, 10–13 February 2013; pp. 1–10. [Google Scholar]

- Austing, J.L.; Tulis, A.J.; Hrdina, D.J.; Baker, D.E.; Martinez, R. Carbon resistor gauges for measuring shock and detonation pressures. I. Principles of functioning and calibration. Propellants Explos. Pyrotech. 1991, 16, 205–215. [Google Scholar] [CrossRef]

- Olsson, M.; Bergqvist, I. Crack lengths from explosives in small diameter boreholes. In Proceedings of the 4th International symposium on Rock Fragmentation by Blasting, Vienna, Austria, 5–8 July 1993; pp. 193–196. [Google Scholar]

- Olsson, M.; Bergqvist, I. Crack lengths from explosives in multiple hole blasting. In Proceedings of the 5th International symposium on Rock Fragmentation by Blasting, Montreal, QC, Canada, 25–29 August 1996; pp. 187–193. [Google Scholar]

- Dehghan-Banadaki, M. Stress-Wave Induced Fracture in Rock due to Explosive Action. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2010. [Google Scholar]

- Nariseti, C. Quantification of Damage in Selected Rocks due to Impact with Tungsten Carbide Bits. Master’s Thesis, University of Toronto, Toronto, ON, Canada, 2013. [Google Scholar]

- Paventi, M.; Mohanty, B. Mapping of blast-induced fractures in rock. In Proceedings of the 7th International Symposium of Rock Fragmentation by Blasting, Beijing, China, 11–15 August 2002; Metallurgical Industry Press: Beijing, China, 2002; pp. 166–172. [Google Scholar]

- Yamin, G. Field Measurements of Blast Induced Damage in Rock. Master’s. Thesis, University of Toronto, Toronto, ON, Canada, 2005. [Google Scholar]

- McHugh, S. Crack extension caused by internal gas pressure compared with extension caused by tensile stress. Int. J. Fract. 1983, 21, 163–176. [Google Scholar] [CrossRef]

- Brinkmann, J. Separating shock wave and gas expansion breakage mechanism. In Proceedings of the 2nd International Symposium on Rock Fragmentation by Blasting, Keystone, CO, USA, 23–26 August 1987; pp. 6–15. [Google Scholar]

- Fullelove, I.; Onederra, I.; Villaescusa, E. Empirical approach to estimate rock mass damage from long-hole winze (LHW) blasting. Min. Technol. 2017, 126, 34–43. [Google Scholar] [CrossRef]

- Hu, Y.; Lu, W.; Chen, M.; Yan, P.; Yang, J. Comparison of blast-induced damage between presplit and smooth blasting of high rock slope. Rock Mech. Rock Eng. 2014, 47, 1307–1320. [Google Scholar] [CrossRef]

- Amnieh, H.B.; Bahadori, M. Numerical analysis for effects of single blast hole in mudstone rock-mass at Gotvand Olya dam. Iran. J. Geophys. (IJG) 2012, 6, 56–72. [Google Scholar]

- Amnieh, H.B.; Bahadori, M. Numerical and field analysis of single-hole blasting mechanism in conglomerate rock mass of Gotvand Olya Dam. Energy Eng. Manag. 2012, 2, 22–31. [Google Scholar]

- Shadab Far, M.; Wang, Y. Probabilistic analysis of crushed zone for rock blasting. Comput. Geotech. 2016, 80, 290–300. [Google Scholar] [CrossRef]

- Shadab Far, M.; Wang, Y. Approximation of the Monte Carlo Sampling Method for Reliability Analysis of Structures. Math. Probl. Eng. 2016, 2016, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Shadabfar, M.; Huang, H.; Wang, Y.; Wu, C. Monte Carlo analysis of the induced cracked zone by single-hole rock explosion. Geomech. Eng. 2020, 21, 289–300. [Google Scholar] [CrossRef]

- Lu, W.; Leng, Z.; Chen, M.; Yan, P.; Hu, Y. A modified model to calculate the size of the crushed zone around a blast-hole. J. S. Afr. Inst. Min. Metall. 2016, 116, 413–422. [Google Scholar] [CrossRef] [Green Version]

- Shadab Far, M.; Wang, Y.; Dallo, Y.A.H. Reliability analysis of the induced damage for single-hole rock blasting. Georisk Assess. Manag. Risk Eng. Syst. Geohazards 2019, 13, 82–98. [Google Scholar] [CrossRef]

| No. | Sources | Parameters | Description |

|---|---|---|---|

| 1 | Rock characteristics | Young’s modulus of rock | |

| 2 | Poisson’s ratio of rock | ||

| 3 | Uniaxial compressive strength of rock | ||

| 4 | Confined compressive strength of rock | ||

| 5 | T | Tensile strength of rock | |

| 6 | Explosive characteristics | Unexploded explosive density | |

| 7 | Ideal detonation velocity | ||

| 8 | Blast hole radius | ||

| 9 | Effective energy of explosive |

| PPV (mm/s) | Effects of Damage |

|---|---|

| <250 | No fracture of intact rock |

| 250–635 | Occurrence of minor tensile slabbing |

| 635–2540 | Strong tensile and some radial cracking |

| >2540 | Complete break-up of rock mass |

| Rock Type | Uniaxial Strength (MPa) | RQD (%) | PPV (mm/s) | ||

|---|---|---|---|---|---|

| Minor Damage | Medium Damage | Heavy Damage | |||

| Soft schist | 14–30 | 20 | 130–155 | 155–355 | >355 |

| Hard schist | 49 | 50 | 230–350 | 305–600 | >600 |

| Shultze granite | 30–55 | 40 | 310–470 | 470–1700 | >1700 |

| Granite porphyry | 30–80 | 40 | 440–775 | 775–1240 | >1240 |

| PPV (m/s) | Tensile Stress (MPa) | Strain Energy (J/kg) | Typical Effect in Hard Scandinavian Bedrock |

|---|---|---|---|

| 0.7 | 8.7 | 0.25 | Incipient swelling |

| 0.1 | 12.5 | 0.5 | Incipient damage |

| 2.5 | 31.2 | 3.1 | Fragmentation |

| 5 | 62.4 | 12.5 | Good fragmentation |

| 15 | 187 | 112.5 | Crushing |

| Case No. | Rock | Explosive | P (g/cm3) | q (MJ/kg) | (km/s) | (mm) | (mm) | (GPa) |

|---|---|---|---|---|---|---|---|---|

| 1 | CL | ANFO | 0.803 | 3.812 | 5.016 | 165 | 82.5 | 3.045 |

| 2 | CL | ANFO | 0.803 | 3.812 | 5.016 | 229 | 114.5 | 3.477 |

| 3 | B | ANFO | 0.803 | 3.812 | 5.016 | 102 | 51 | 2.061 |

| 4 | B | ANFO | 0.803 | 3.812 | 5.016 | 165 | 82.5 | 3.148 |

| 5 | B | ANFO | 0.803 | 3.812 | 5.016 | 229 | 114.5 | 3.595 |

| 6 | CL | WR ANFO | 0.994 | 3.918 | 5.829 | 51 | 25.5 | 2.016 |

| 7 | CL | WR ANFO | 0.994 | 3.918 | 5.829 | 102 | 51 | 4.033 |

| 8 | CL | WR ANFO | 0.994 | 3.918 | 5.829 | 165 | 82.5 | 4.974 |

| 9 | CL | WR ANFO | 0.994 | 3.918 | 5.829 | 229 | 114.5 | 5.44 |

| 10 | B | WR ANFO | 0.994 | 3.918 | 5.829 | 51 | 25.5 | 2.085 |

| 11 | B | WR ANFO | 0.994 | 3.918 | 5.829 | 102 | 51 | 4.169 |

| 12 | B | WR ANFO | 0.994 | 3.918 | 5.829 | 165 | 82.5 | 5.141 |

| 13 | B | WR ANFO | 0.994 | 3.918 | 5.829 | 229 | 114.5 | 5.623 |

| Case No. | Esen et al. [2] | Il’yushin [59] | Szuladzinski [62] | Djordjevic [72] | Kanchibotla [73] |

|---|---|---|---|---|---|

| 1 | 372 | 1269 | 379 | 466 | 1192 |

| 2 | 564 | 1761 | 526 | 647 | 1654 |

| 3 | 67 | 402 | 108 | 139 | 339 |

| 4 | 143 | 651 | 175 | 225 | 549 |

| 5 | 217 | 903 | 242 | 312 | 762 |

| 6 | 88 | 441 | 132 | 186 | 476 |

| 7 | 277 | 881 | 264 | 372 | 953 |

| 8 | 513 | 1426 | 427 | 602 | 1541 |

| 9 | 756 | 1979 | 593 | 836 | 2139 |

| 10 | 34 | 239 | 61 | 90 | 219 |

| 11 | 107 | 478 | 122 | 179 | 439 |

| 12 | 198 | 774 | 197 | 290 | 710 |

| 13 | 291 | 1074 | 273 | 403 | 985 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shadabfar, M.; Gokdemir, C.; Zhou, M.; Kordestani, H.; Muho, E.V. Estimation of Damage Induced by Single-Hole Rock Blasting: A Review on Analytical, Numerical, and Experimental Solutions. Energies 2021, 14, 29. https://doi.org/10.3390/en14010029

Shadabfar M, Gokdemir C, Zhou M, Kordestani H, Muho EV. Estimation of Damage Induced by Single-Hole Rock Blasting: A Review on Analytical, Numerical, and Experimental Solutions. Energies. 2021; 14(1):29. https://doi.org/10.3390/en14010029

Chicago/Turabian StyleShadabfar, Mahdi, Cagri Gokdemir, Mingliang Zhou, Hadi Kordestani, and Edmond V. Muho. 2021. "Estimation of Damage Induced by Single-Hole Rock Blasting: A Review on Analytical, Numerical, and Experimental Solutions" Energies 14, no. 1: 29. https://doi.org/10.3390/en14010029